Summary:Aluminum Producers Emit Some of the World's Most Damaging Greenhouse Gases

This is a summary of an article from Inside Climate News, originally titled "Why Chinese Aluminum Producers Emit So Much of Some of the World’s Most Damaging Greenhouse Gases".

Problem

PFCs

Some aluminum factories emit unreasonably large amounts of PFCs - especially in China where there are weak regulations.

More than half of the aluminum in the world is produced in China, but it is responsible for 81 percent of the industry’s emissions of PFCs. Simple automation could go a long way toward cutting them.

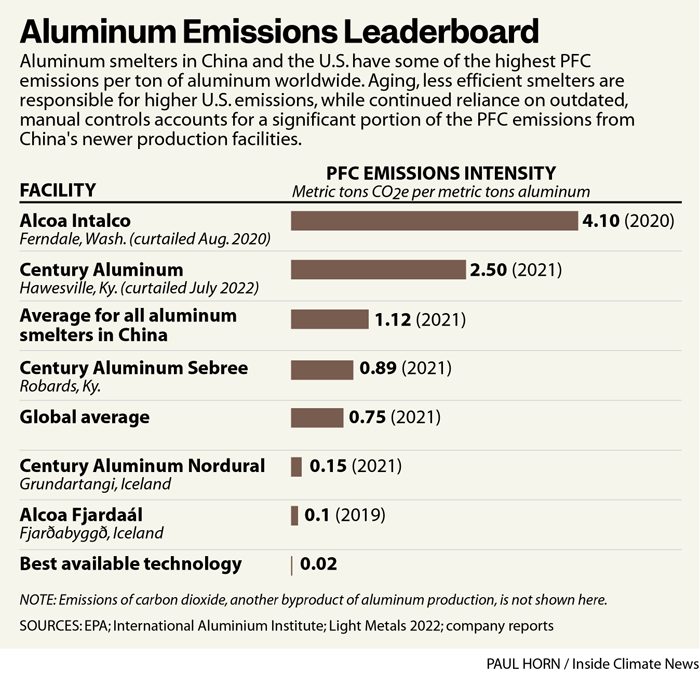

The following chart shows the PFC emissions, expressed in tonnes of CO2-equivalent (CO2e) per tonne of aluminum produced. This varies widely by factory.

Just for perspective

Other greenhouse gas emissions:

Aluminum production requires a lot of electricity - which adds 5 to 16 tons of CO2 per ton of aluminum, if the electricity is generated from fossil fuels (as most of the world's electricity currently is).

Natural gas power plants (best case, high efficiency, no fugitive emissions):

[www.sciencedirect.com/topics/engineering/aluminum-production Aluminum Production - an overview - ScienceDirect Topics]

https://www.eia.gov/environment/emissions/co2_vol_mass.php

Simpler/older natural gas plants (no combined cycle) have only an efficiency of 33%, same as [coal_power_plant.efficiency].

Read more: https://energyeducation.ca/encyclopedia/Natural_gas_power_plant

(calculation loading) Coal power plants:

https://www.energy.gov/fecm/transformative-power-systems

(calculation loading)

Solution

The article describes in detail how factories can avoid almost all PFC emissions.

Overview

How aluminum metal is made:

- Smelting: Aluminum oxide (mined from the earth) is placed in a molten salt bath (which contains fluoride salts) and electricity is applied. This converts the aluminum oxide into pure metallic aluminum.

How PFCs are emitted:

- When the concentration of aluminum oxide gets too low in the mix, the electricity causes the salts to react with the carbon anodes, producing the gases CF4 and C2F6.

Which factories emit the most PFCs:

- Any that rely on workers to visually monitor the aluminum oxide levels, manually turn the mixture by poking it with a stick, etc.

Solution:

- Automated systems, controlled by sensors.

The article mentions that the solution could also be profitable (win-win), by improving energy efficiency.

Unanswered questions

There clearly needs to be more talk about the physical costs of such new systems. What would be the environmental impact of creating all this new factory equipment, and how would it compare to the PFC emissions avoided? [RESEARCH needed]

I would wager that the new systems would be a net benefit for the environment - but that's purely a guess from intuition. Detailed data is hard to come by, but we should at least try to make a rough estimate based on simple costs.